The development and utilization of modern-day surgical instruments and medical devices have revolutionized patient care. From orthopedic tooling to dental reamers, these instruments play a pivotal role in ensuring efficient procedures and optimal outcomes. To fully realize these benefits, however, the significance of biochrome coatings for aluminum medical devices can’t be overstated.

Here, we’ll provide an overview of common types of metal fatigue and how AL-COAT® biochrome coatings provide protection and enhance the overall appearance of aluminum surgical instruments and medical devices.

Types of Aluminum Metal Fatigue and Failure

Aluminum, prized for its lightweight nature and excellent biocompatibility, is often employed in medical equipment for its unique combination of strength and malleability. However, with the repetitive stresses inherent in many medical applications, microscopic defects such as manufacturing imperfections, corrosion, and external mechanical loads can lead to fatigue cracks, posing potential risks to the durability and safety of these vital instruments. Here are some of the top causes of metal failure in aluminum medical devices and surgical tools.

Cyclic Fatigue

Cyclic metal fatigue refers to the process by which a material, in this case, aluminum, becomes weakened and eventually fails due to repeated, fluctuating stress cycles — rather than a one-time, static load.

Even if these cyclic stresses are well below the material’s ultimate tensile strength, the continuous loading and unloading can induce the initiation and subsequent propagation of microscopic cracks. Aluminum, like all metals, has grain boundaries, inclusions, and potential casting or manufacturing imperfections. As a result, these inherent flaws can serve as initiation points for these microscopic cracks.

The major subtypes of cyclic fatigue that aluminum medical devices can experience include:

Fretting Fatigue

This is a specialized form of wear and fatigue, particularly relevant in applications where two contact surfaces experience slight relative motion under applied load. This can lead to the removal of material from surfaces and introduce cracks that can progress to full fatigue failure. Many medical devices have components that fit together, like screw joints, modular parts, or adjustable features. When these are in use, they may experience cyclic loading, leading to fretting between the mating surfaces. Since aluminum is softer compared to metals like steel or titanium, it is more susceptible to the abrasive effects of fretting, particularly if paired against a harder material.

Finally, fretting can often be accompanied by a specific form of corrosion known as fretting corrosion. In the case of aluminum, which naturally forms a protective oxide layer, the repeated micro-motions can disrupt this layer, exposing the fresh aluminum underneath to corrosive agents and accelerating wear.

Bending Fatigue

Bending fatigue is a type of metal fatigue that occurs when a material experiences repeated bending or flexing stresses. Many aluminum medical instruments, especially those used in orthopedic and surgical applications, undergo bending motions during use. As the aluminum device undergoes repeated bending, microscopic cracks can initiate stress concentrations.

Torsional Fatigue

Similar to bending fatigue, torsional fatigue occurs when a material goes through repeated motions, such as twisting or rotating. Similar to other types of fatigues, stress concentrations can occur at points of abrupt geometry changes or notches, where the stress distribution is uneven. These stress concentrations can become sites for crack initiation of aluminum medical devices under cyclic loading.

Axial Fatigue

Axial stresses arise when an aluminum medical device experiences alternating tensile and compressive loads along its longitudinal axis. These stresses can occur during device insertion, manipulation, or when devices support or bear loads within the body. Like other types of fatigue, repetitive axial loading can lead to the initiation of small cracks — eventually leading to device failure.

Corrosion Fatigue

Corrosion fatigue is a complex interplay of mechanical and chemical factors — the result of the combined action of cyclic fatigue and a corrosive environment. Unlike pure fatigue, where the cyclic loading alone would lead to failure, or general corrosion, where the environmental exposure alone would cause damage, corrosion fatigue happens more rapidly due to the synergistic effects of both mechanical loading and environmental corrosion.

In aluminum medical devices and instruments, the repetitive nature of the stresses induces microscopic cracks on the surface or subsurface of the metal. Add to the mix a corrosive environment — biological fluids, sterilization processes such as autoclaving, cleaning agents and disinfectants, saline or salt solutions, to name a few — and these microcracks can initiate much earlier than they would in a benign environment.

Once initiated, these cracks propagate more rapidly in corrosive conditions. The cyclic loading drives the crack forward while the aggressive environment continuously weakens the material around the crack tip. As the crack propagates, the process gets accelerated. The environmental agents can penetrate deeper into the material through the crack, causing localized corrosion, like pitting, which in turn further weakens the structure and promotes even faster crack growth. Given these potential challenges, it’s critical to employ coatings that can protect all types of aluminum instruments and surgical tools from corrosion and wear.

Fighting Metal Failure and Fatigue

Biochrome coatings serve as the first line of defense against corrosion, shielding aluminum medical devices and surgical equipment from biological interactions and metal failure. The first biochrome coating to perform and pass the Tripartite Guidelines Testing for Biocompatibility, ME-92® coatings, including AL-COAT®, reduce bacterial adherence, facilitate easier cleaning and decontamination, and maintain surface integrity after repeated sterilization cycles. Here are some AL-COAT® applications that improve medical device longevity and functionality while promoting patient safety.

Surgical instruments in treatment of bone fractures

Biochrome Coatings for Endoscopic Cutters

Endoscopic cutters are surgical instruments used in minimally invasive procedures to cut, dissect, or remove tissue through small incisions. These devices often consist of a long shaft to access hard-to-reach areas within the body, with a cutting mechanism at the tip. The design dictates whether the cutting action is manual, actuated by the surgeon’s hand, or powered by an external source. Cutters, needing to be sharp, reliable, and precise for the sensitive tasks they perform, face various types of metal fatigue from their repetitive and demanding usage.

Metal Failure Challenges for Endoscopic Cutters

- Cyclic Fatigue: Every time the cutter is used to snip tissue, it undergoes a load cycle. Over many procedures or even during a single prolonged procedure, the cumulative effect of these load cycles can lead to fatigue. With repeated use, the cutting jaws or blades can develop microscopic cracks that propagate over time, leading to the failure of the cutting mechanism. Due to the minimally invasive nature of endoscopic surgeries, there is limited visibility and access to the surgical site. Therefore, a tool failure can complicate the procedure and may even necessitate converting to a more invasive approach to resolve the issue.

- Bending Fatigue: These instruments may experience bending stresses during use, especially if they are used to navigate tight spaces within the body. Bending fatigue can lead to localized stress concentrations and crack initiation.

- Fretting Fatigue: Fretting fatigue can occur at contact points between different components of the cutter, such as the blade and the handle. The opening and closing of the cutter jaws can lead to wear at the hinge or pivot points, which could compromise the tool’s precision and effectiveness.

Benefits of AL-COAT® for Endoscopic Applications

- Wear Resistance: AL-COAT® offers a durable and wear-resistant surface, reducing friction at critical points of contact within the endoscopic cutter, such as blade edges and moving parts. This helps minimize the effects of fretting and bending fatigue.

- Corrosion Resistance: Endoscopic cutters are often used in a moist, corrosive environment within the body. AL-COAT® protects the instrument from degradation and corrosion-related fatigue.

- Reduced Friction: AL-COAT® provides reduced coefficient of friction, decreasing the forces exerted on the instrument during cutting and manipulation and lowering the stress levels that contribute to fatigue.

- Biocompatibility: AL-COAT® ensures that the endoscopic cutter’s contact with bodily tissues is safe and does not trigger adverse reactions.

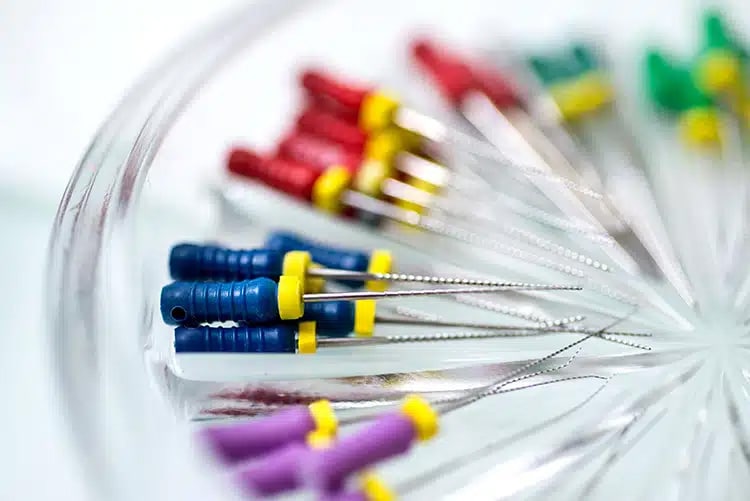

Biochrome Coatings for Dental Reamers

During endodontic procedures, dental professionals primarily use surgical instruments like dental reamers to clean, shape, and enlarge the root canal system of a tooth. These tools, including files and broaches, are crucial for ensuring the tooth’s root canal system is thoroughly cleaned of bacteria and debris before sealing with a filling material.

Metal Failure Issues for Dental Reamers

- Cyclic Fatigue: During root canal preparation, dental reamers rotate and engage with the tooth structure, facing cyclic loading. This cyclic loading can lead to the initiation and propagation of fatigue cracks.

- Bending Fatigue: The complex and curved anatomy of root canals may subject dental reamers to bending stresses as they navigate the canal’s contours. Bending fatigue can occur due to the repeated flexing of the instrument.

- Fretting Fatigue: Fretting fatigue can occur at contact points between the reamer and the canal walls. As the instrument rotates and advances, there may be slight relative motion at these contact points, leading to wear and fatigue over time.

Benefits of AL-COAT® for Dental Applications

- Wear Resistance: The wear-resistant properties of AL-COAT® reduce friction and wear as the dental reamer interacts with tooth structure. This is particularly important for minimizing the effects of fretting fatigue and wear at contact points.

- Corrosion Resistance: A wet and potentially corrosive environment within the oral cavity uses dental reamers. AL-COAT® protects the instrument from degradation.

- Reduced Friction: The low-friction benefit of AL-COAT® reduces the forces exerted on the instrument during rotary motion, potentially reducing stress levels.

- Biocompatibility: AL-COAT® wards off bacteria and ensures that the reamer’s contact with oral tissues is safe.

Medical Laparoscopic Surgical Instrument Handle

Biochrome Coatings for Medical Handles, Housings, and Tubing

Medical device components are the individual parts or elements that come together to form a complete medical device. These components can be structural, electronic, mechanical, optical, biological, material, and disposable, and therefore vary widely in function, size, and complexity depending on the type of device. Designers and manufacturers meticulously create these devices to meet stringent regulatory and quality standards, ensuring their safety and efficacy for the intended application. Here, we’ll look at structural components, such as medical handles, housings, and tubing.

Metal Failure Issues for Medical Device Components

- Cyclic Fatigue: Handles and tubing, when subjected to repeated loading and unloading, can undergo cyclic fatigue. This can occur due to mechanical stresses from handling, manipulation, or fluid flow cycles.

- Bending Fatigue: Handles, housings, and tubing that are flexible or subject to bending during use can be prone to bending fatigue, which arises from repeated bending stresses.

- Torsional Fatigue: Components that undergo twisting or rotational motion, like handles used for torque application, may experience torsional fatigue due to the twisting forces applied to them.

- Axial Fatigue: Tubing and elongated components that experience axial loading, such as those used for fluid transport, can undergo axial fatigue from repeated tensile or compressive stresses.

Benefits of AL-COAT® for Medical Device Components

- Enhanced Durability: AL-COAT® can improve the overall durability of aluminum components by providing a protective layer that resists wear, friction, and environmental factors.

- Fatigue Resistance: AL-COAT® enhances the strength of aluminum, making medical components more resistant to crack initiation and propagation under cyclic loading.

- Corrosion Protection: Corrosion-resistant properties AL-COAT® can prevent or delay the onset of corrosion-related fatigue, particularly important for components exposed to bodily fluids or other corrosive environments.

- Reduced Friction: Since AL-COAT® has low-friction properties, the coating will reduce the forces generated during bending, torsion, or axial loading.

- Biocompatibility: AL-COAT® ensures that components in contact with biological tissues or fluids do not cause adverse reactions.

AL-COAT®: Protection, Longevity, and Appeal

AL-COAT® is a precise, biocompatible, pure metallic chromium coating applied to aluminum.

Completely inert, non-magnetic, USP Class VI, Tripartite/ISO and Anti-Microbial, AL-COAT® improves the physical appearance of medical instruments and, more importantly, provides functional enhancements to their performance.

Our metallurgical and materials consulting, research, and testing experts at the Armoloy Innovation Center are here to help you determine the right coating and finish to meet your specific needs.