Improve the Function, Durabilty and Appearance of Medical Instruments and Devices

Our Biocompatible Coatings Prevent Discoloration, Wear and Improve the Performance of Your Equipment.

Call or Email Us Today for an Engineered Solution:

1-401-831-9200

Since 1992, the Industry Leader in Biocompatible Chromium Coatings

The ME-92® and ALCOAT® Coatings are biocompatible, pure-metallic chromium coating designed to improve the function and appearance of medical instruments and devices. The coating is completely inert, non-magnetic , USP Class VI, Tripartite/ISO and Anti-Microbial.

The ME-92 Operations coating technology is a proprietary process that electrolytically applies a precise, pure metallic, zero valence chromium coating to the device without altering the integrity of the base material. Processed at a 30,000 sf facility in Providence, Rhode Island in a clean, latex-free environment. ME-92® and ALCOAT® are licensed products and processes developed and managed by The Armoloy Corporation laboratories.

Properties:

- Arrests corrosion from sterilization and laser marking while maintaining new appearance

- Increases wear resistance

- Maintains cutting edges

- Provides a hard, scratch resistant, nonstick, easy clean surface

- Increases surface hardness

- Eliminates galling, fretting, spalling

- Ability to remove and reapply

- Arrests metallic debris and particulate matter

- Provides smooth sliding surfaces

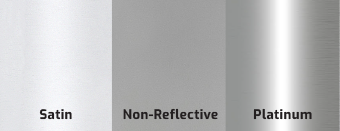

- Reduces high intensity light reflection/refraction and glare

- Provides long lasting, clean, pristine new appearance

- Chemical resistant

- Hydrophobic

Biocompatibility:

ME-92 Operations was the first chrome coating company to perform and pass the Tripartite Guidelines testing for biocompatibility. The current standard is ISO 10993 and ME-92’s Coatings have also successfully passed the requirements for biocompatibility to this standard.

Anti-Microbial Technology Research concluded that the ME-92® and ALCOAT® Coatings:

- Reduced bacterial adherence

- Facilitated easier cleaning and decontamination

- Maintained the surface integrity after repeated sterilization cycles

Adhesion:

The ME-92® coating is bonded directly to the base material. This unique process enables the coating to adhere absolutely. The ME-92® coating will not chip, flake or peel. The coating is highly ductile and will not separate from the base material even when twisted, flexed or impacted without intermediate layering.

Sterilization:

ME-92® coatings are compatible with the following sterilization procedures:

- Steam Autoclave

- STERIS SYSTEM 1

- STERRAD Sterilization

- Gamma X Ray

- Bleach Exposure

- Boiling

- Detergent scrubbing

- STERIS EtO

Compatible Base Metals:

The ME-92® coating is an excellent candidate for application to nearly every base metal type, from tool steels such as S-7 and H-13, to bearing steels such as 52100 and 8620, to cold roll, hot roll, high-carbon and low-carbon steels, to cast iron, stainless steel, bronze, copper, and brass. Absolute adhesion to the substrate is guaranteed.

ALCOAT® for formulated and perfected specifically for application on Aluminum substrates.