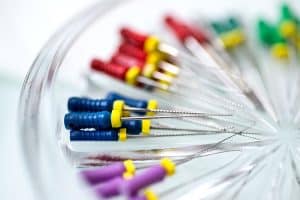

Top Medical Device Coatings to Improve Safety and Performance

Biocompatible medical device coatings are essential for improving the performance, safety, and appearance of surgical instruments, equipment and components. In this article, we’ll explore the top medical device coatings, the benefits they provide, and how ME-92...

Top 5 Frequent Questions about Biocompatible Coatings for Surgical Instruments

Choosing biocompatible materials for surgical instruments is of the highest importance in the medical and dental industries. To fully deliver on form and function, however, biocompatible coatings should also factor into the product equation. Developed for the...

Proud To Be the Pioneer in Biocompatible Coatings

Healthcare organizations understandably have high expectations for the chromium coatings applied to their stainless-steel and aluminum instruments and devices. None is more critical than biocompatibility. They want a coating that prevents corrosion,...

Addressing Nickel Sensitivity With Chromium Coatings

Nickel is a hard, ductile metal that is silvery-white in color. It is present in some types of stainless steel, including formulations that medical device manufacturers often use in producing instruments and devices. Its physical characteristics make it useful in that...

The Benefits of Working With a Start-to-Finish Coatings Provider

A couple decides to go out for a nice dinner. There is no reason they can’t get appetizers at one restaurant, a salad at another, their entrees at a third, and dessert somewhere else. And if they’re up for a significant amount of travel between sites, time spent...

The Case for Chromium Coatings

Every manufacturing process and material has its detractors. Chromium coatings for stainless-steel medical instruments are no exception. Despite the many benefits this article lists below, there are still those who criticize chromium. What do they say? For one...

Medical Instrument Chromium Coatings: Why Precision Masking Is Essential

Having a provider like ME-92 Operations apply a chromium coating to medical instruments produces many benefits. The layer provides greater strength and durability, an easily cleaned and sterilized surface, corrosion prevention, and many other advantages. ...

A Look Inside the ME-92 Process: How We Ensure Quality and Compliance

Two areas where ME-92 Operations strives for ever-higher levels of excellence are product quality and regulatory compliance. And we’re honored that your clients and the regulatory entities we deal with will tell you that we continually hit the targets we set for...