Biocompatibility, Chromium Coating

A critical factor in ensuring the longevity and safety of stainless steel surgical instruments is their resistance to corrosion. A naturally occurring process, corrosion is the destruction or deterioration of a material when the substance is in contact with air,...

Biocompatibility, Chromium Coating

In the intricate medical device and equipment manufacturing world, adherence to stringent quality systems such as ISO 10993 and FDA 21 CFR820 is paramount. Devices that come into direct or indirect contact with the human body are evaluated, explains the FDA,...

Biocompatibility, Chromium Coating

In an era of rapid advancements in medical technology, the tools and equipment that facilitate these breakthroughs need to be equally innovative. Ensuring the sterility and integrity of medical packaging is critical to this technological frontier. At the heart of this...

Biocompatibility, Chromium Coating

From the medical industry and beyond, durable, anti-corrosive aluminum is essential to performance. Aluminum is used extensively for components in various applications because of its unique combination of properties – including that it is especially well-suited to...

Biocompatibility, Chromium Coating

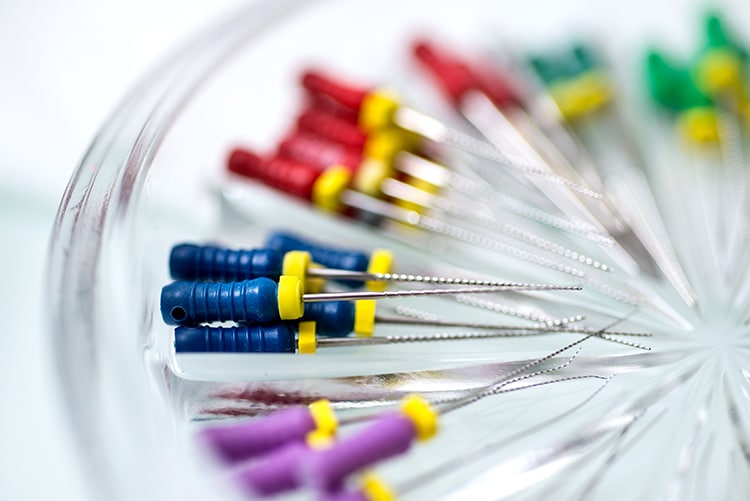

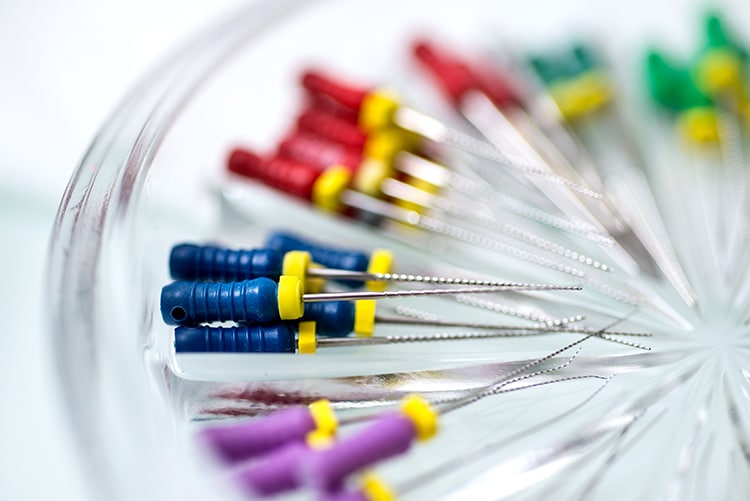

The development and utilization of modern-day surgical instruments and medical devices have revolutionized patient care. From orthopaedic tooling to dental reamers, these instruments play a pivotal role in ensuring efficient procedures and optimal outcomes. To fully...

Biocompatibility, Chromium Coating

Biochrome coatings are of paramount importance for surgical tools, instruments, and medical applications. Not only do biochrome coatings provide protection, longevity, and aesthetic appeal, but they are also very versatile. They can be included proactively, in the...

Biocompatibility, Chromium Coating

A branch of physics that analyzes the behavior of liquids and gases, fluid mechanics is a critical engineering principle concerned with the study of forces and motion in fluids. Fluid mechanics reveals the effects of pressure, velocity, density, viscosity, and other...

Biocompatibility, Chromium Coating

Biochrome coatings protect all types of tools from corrosion, abrasion, friction, and wear, greatly improving the performance, longevity, and physical appearance of stainless steel surgical instruments and medical-grade devices. Completely inert, non-magnetic,...

Biocompatibility, Chromium Coating, Friction

In our previous medical device design discussions, we explained methods to reduce wear in stainless steel, and how utilizing thin dense chrome protective coatings during the design phase can extend the life of your applications. Now, we’re going to shift our focus to...

Biocompatibility, Chromium Coating

Two distinct properties, wear and friction, are important considerations in the design of medical devices, equipment, and the tooling used for manufacturing surgical instruments. Many medical applications require special attention to reduce or eliminate...